In the small town of Fontevraud L’Abbaye in the Loire Valley in France, since 1974 there is a renowned handmade soapmaker, Savonnerie Martin de Candre. Since its founding 40 years, Martin de Candre soap manufacture (MdC) is dedicated to producing excellent quality handmade soap products, as they say, using the classic process of Marseilles soap.

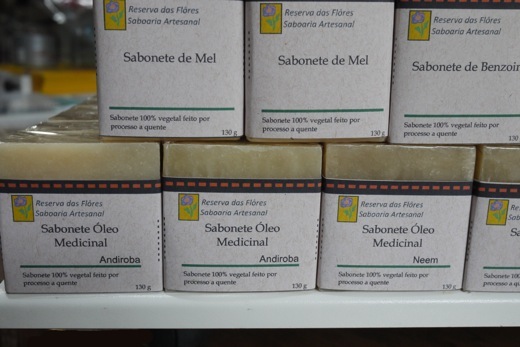

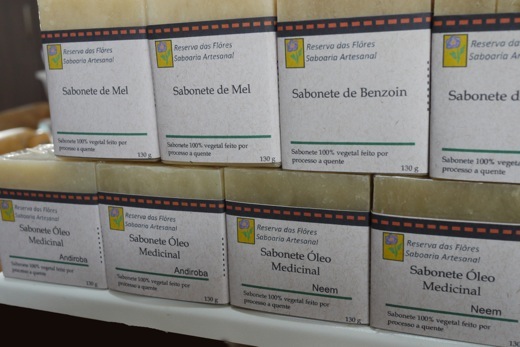

The soap (cream) shaving of Martin de Candre is considered the best in the world, they have a line of Marseille soap (for cleaning) with olive, coconut and palm, a line call huile de palme that is made with olive , coconut and palm oil and a third, huile d’olive, only with olive and coconut.

All these products have a premium price ranging 9 to 16 euros for soaps bars and shaving soap can cost 23 euros one container of 50 grams.

They claim that make the process of Marseilles soap which is a full boiling process where the soap is rinsed with salted water and glycerin is removed. In reality MdC makes a fairly conventional handmade hot process, which uses a mechanical stirrer to stir the mass during saponification and the lot size is less than 25 kg. This can be seen in the few photos on their website and also a video report produced by a French TV.

But what caught my attention was the procedure them to dry for eight months the soap bars and for 5 months the shaving soap! Intriguing because the hot process soap has saponified out and therefore safe and drying 15 days is enough to have the necessary hardness for lasting use. A soap made by Cold Process is ready for use in about 20 days. Here comes the question, why make a process more complex, lengthy and expensive process that is hot, if I can make cold process much simpler, faster and cheaper? After leaving it for 8 months a soap made by hot or cold, theoretically they would have the same performance. It is clear that the hot process has the advantage of being able to incorporate sensitive components after alkaline saponification, which preserves these components, in which process cold is not possible.

I decided to design a test to compare the properties of a soap made by cold process and the same made by hot process and also compare the influence it has drying time in soap performance in both cases.

Hot Process with Continuous Stirring – HPCS

A handmade hot processs is normally done using as source of heating a double boiler or an electric slow cooker (crock pot), and the mass is homogenized manually from time to time to enable a comprehensive saponification.

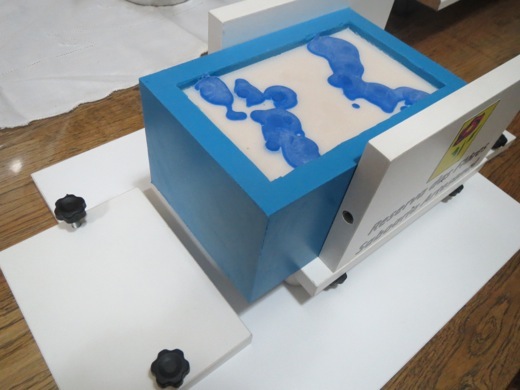

To keep the process more akin to the Martin de Candre hot process, I designed a system called Hot Process Continuous Stirring – HPCS. Obviously not is an innovation, but in the artisanal scale not seen anyone use a similar system.

Thus, a comparative test between soaps produced by two distinct processes, eventually drifting to the development of a third way to do a hot process that is the HPCS.

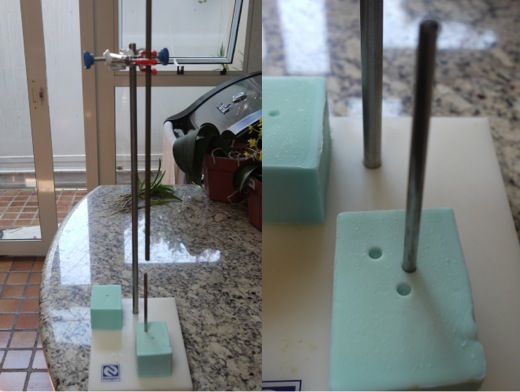

This is the setup of the equipment to do the HPCS – an electric heater (this is a laboratory magnetic stirrer), a mechanical stirrer (used with digital speed control) and a digital thermometer.

Here’s a video I made showing the HPCS to make benzoim soap (12 minutes):

http://www.youtube.com/watch?v=aYyWmYJ51EY

Soaps Testing

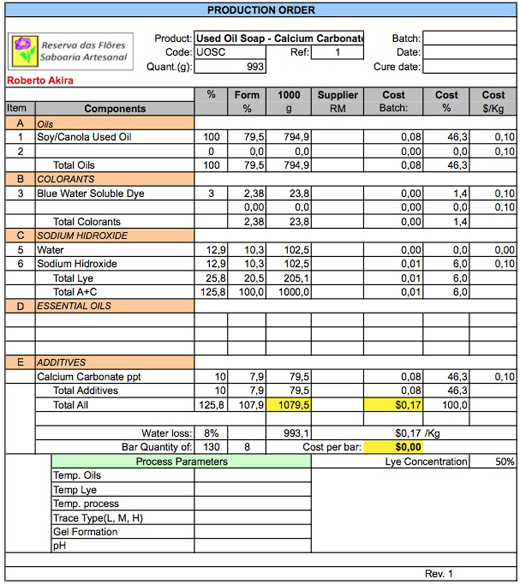

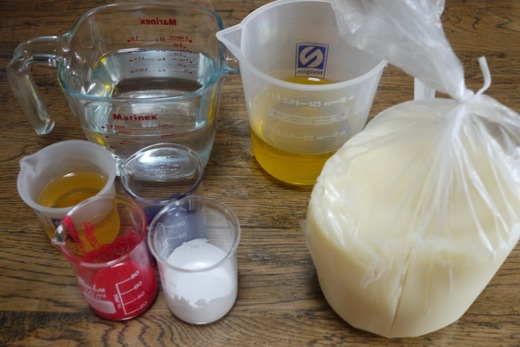

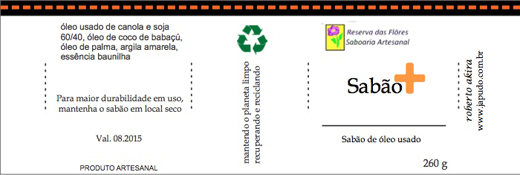

The Martin Candre in your palm line has a honey soap and a benzoim (tonkinense Styrax) soap, and were made simlilar these for testing. The oil soap composition was: olive / palm kernel / palm – 60/25/15, SF 5% and lye concentration of 30%. The comparative test will be done with the honey and the benzoim was done to confirm and optimize the process HPCS. You can not make a regular cold process with benzoim because of the need to dilute the benzoim oil resin with ethanol, which would give the defect of seizing on mass.

On the left the soap made with honey HPCS, the other by conventional cold process. The color is dark in the cold process due to carbonization of the sugar honey by lye.

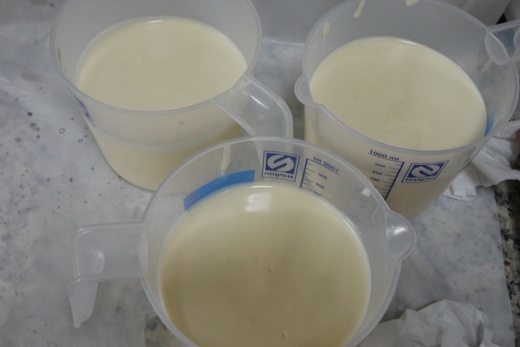

The two blocks of honey soaps , 3.5kg.

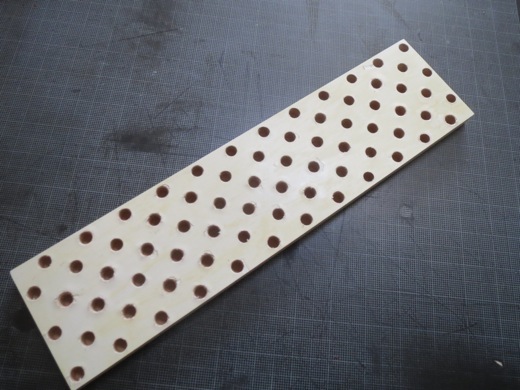

Cut surface finish of the honey soap by hot process with continuous stirring using Flex Cutter.

Two bars 305 x 80 mmm

Two bars 305 x 80 mmm

Finishing the top of bars

Finishing the top of bars

The two bars finished in the dimensions of 305 x 80 x 60 mm.

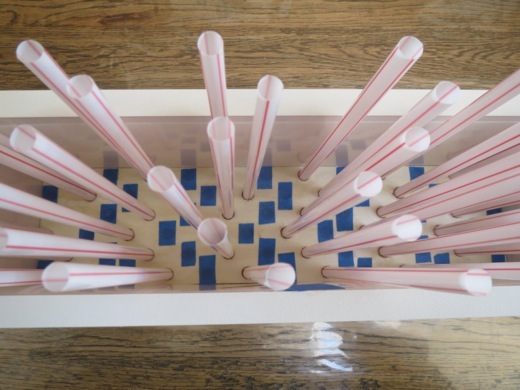

Cutting individual bars using Flex Cutter.

Cut with precision Cutter Flex.

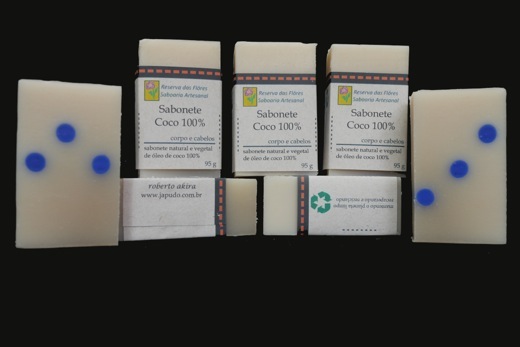

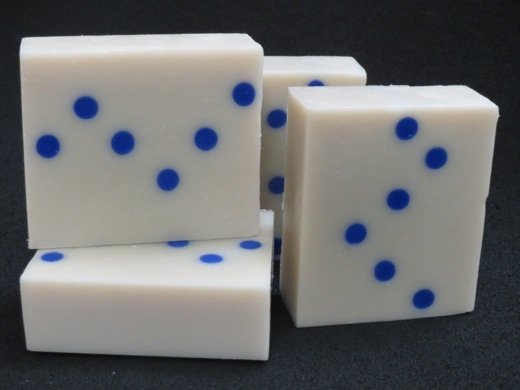

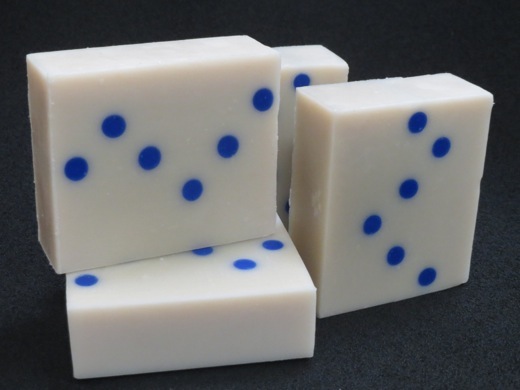

All individual bars 80x60x30 mm, 135 grams.

Cut the block of honey soap made with cold process.

All bars of honey soap CP, 90x60x25 mm, 130 grams.

The two soaps will be used in the comparison between CP and HP.

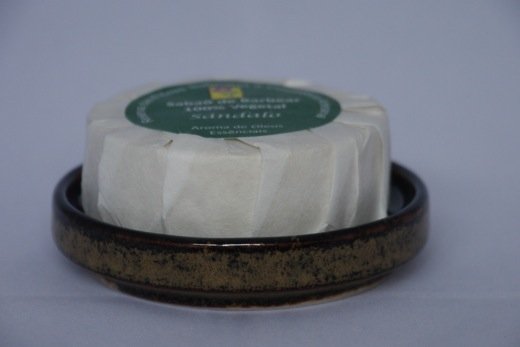

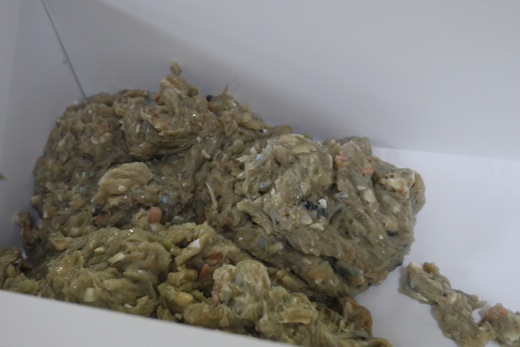

Benzoim soap made by Hot Process Continuous Stirring – HPCS

This soap was made to confirm and improve the HPAC process.

———————————————————————————————-

———————————————————————————————-

Savonnerie Martin de Candre: http://savonnerie-martin-de-candre.com/fr/