Today packing up my mess I found a box full of soap, soaps made in 2009 and 2010, all in perfect condition, packed in cellophane.

Among the various soaps there was a Castile Soap 100% Olive, a pure, with nothing and another with green clay, both odorless. It was a great find because it is difficult to have a soap with such longevity!

Immediately remembered the discussion about the 100% olive oil soap that somehow got me positioned as a critic of such mono-oil soap by cold process handmade.

Immediately remembered the discussion about the 100% olive oil soap that somehow got me positioned as a critic of such mono-oil soap by cold process handmade.

This Castile soap as it is called, has nothing of the old Castile soap led to the Mediterranean lands of Spain by the Moors in the 11th century, who knew the techniques of Aleppo soap.

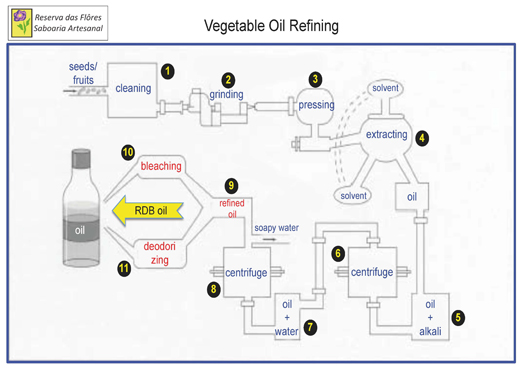

In the absence of fruit bay oil, soap made only with the olive in the hot boiling process and with the use of soda ash (barilla) as alkali for saponification and salt solution to precipitate the soap, which removes glycerol.

Two centuries later this soap was taken to Marseille in the 13th century and began production of the famous and traditional Marseille Soap, which unfortunately the company producing today are in dire straits.

Obviously today we can not witness the performance of the original Castile soap but can be a base soap from Marseille who inherited much of Castilla. This type of soap has a peculiar characteristic and easily noticed to do a little foam and small foam.

Olive Soap 100% handcrafted from cold process inherited this trait or “defect” of Marseille Soap and probably the original Castile. Also with one aggravating the soap has hardness in use, its dissolution is too large in contact with water, becomes sticky and forms a residual mass dissolved and the soap scum on the surface.

However inherited the fabulous feature of conditioning, providing hydration and softness to the skin, without equal.

As contact is in verse and prose that 100% olive soap made by cold process goes along the extensive drying time, some recommend 6-9 months, acquiring the best properties as a whole and I was now in hands of Castile Soap 100% olive with 3-year-old just said I needed to confirm this.

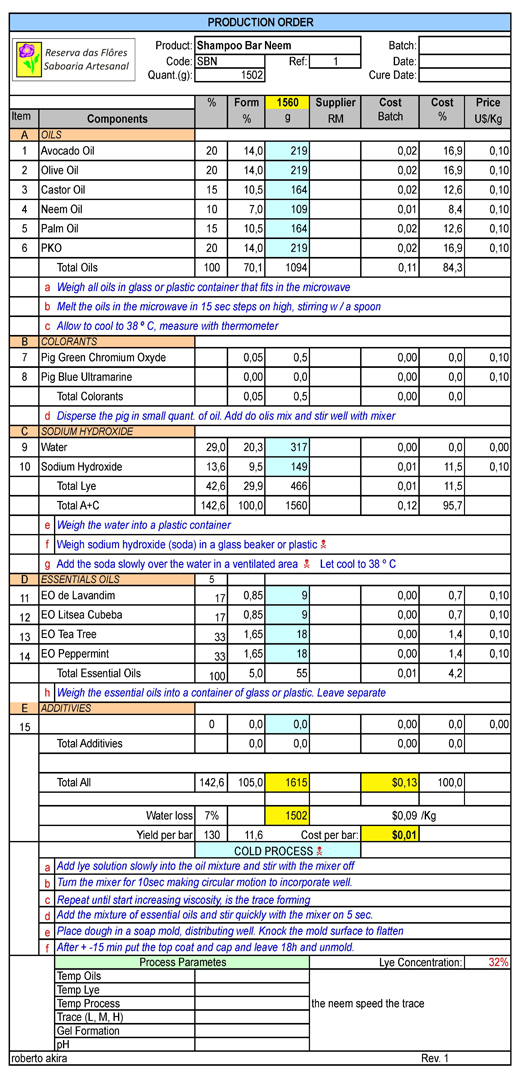

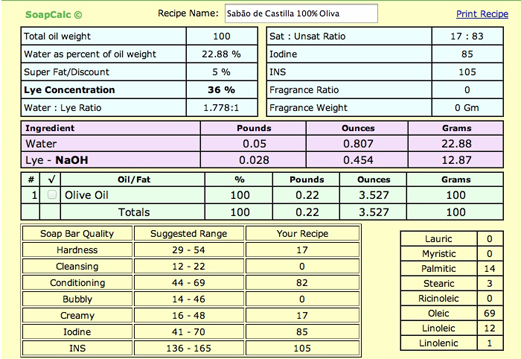

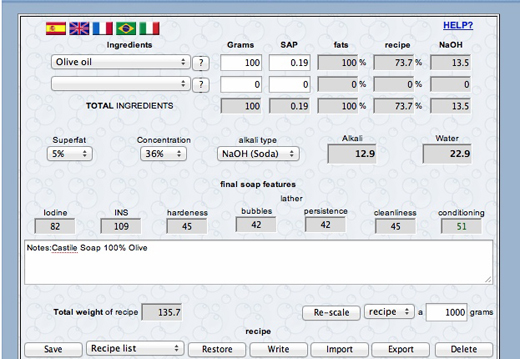

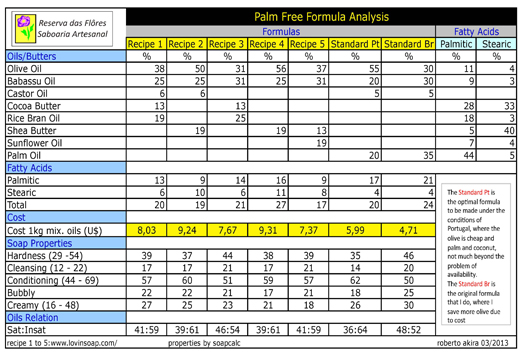

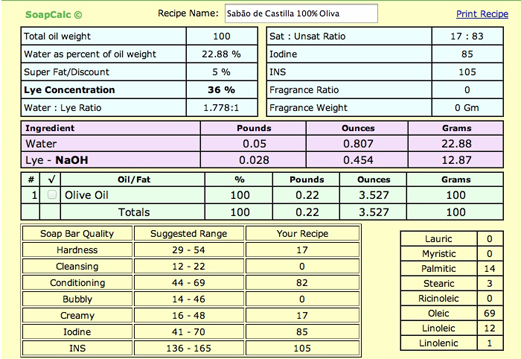

The online calculators give an estimate of the performance of soap in five properties, which are: hardness, cleanliness, conditioning, lather and creaminess / persistence.

The calculators are the most used and Soapcalc Mendrulandia. The Soapcalc, more critical, pointing to the Castile soap the following deficiencies: zero cleaning , zero bubbly and 17 for hardness and 17 for creaminess.

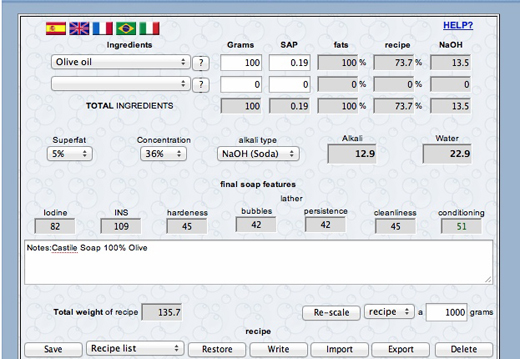

The Mendrulandia the less critical, points out the shortcomings of foam and persistence at the lower limit and hardness and cleanliness halfway from ideal.

The Mendrulandia the less critical, points out the shortcomings of foam and persistence at the lower limit and hardness and cleanliness halfway from ideal.

The Mendrulandia the less critical, points out the shortcomings of foam and persistence at the lower limit and hardness and cleanliness halfway from ideal.

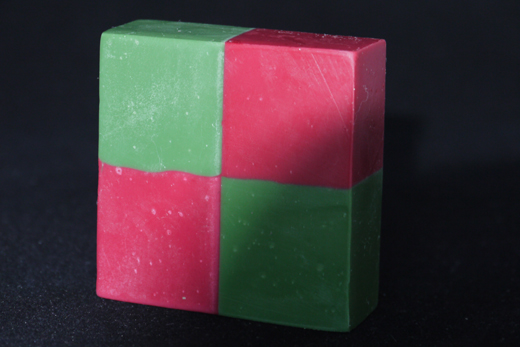

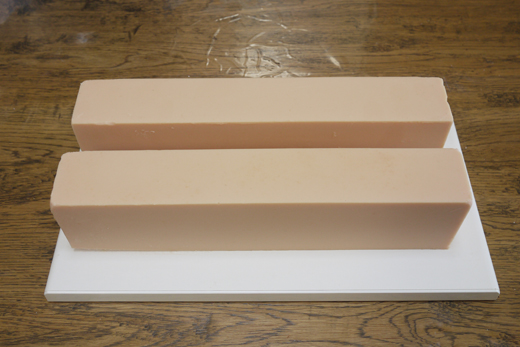

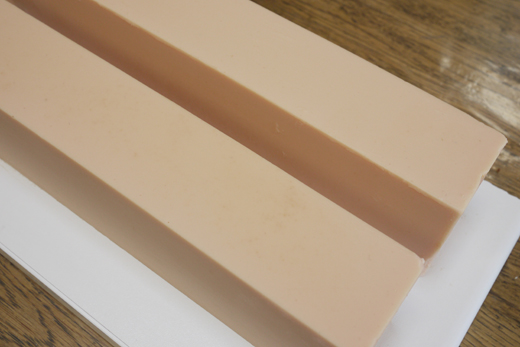

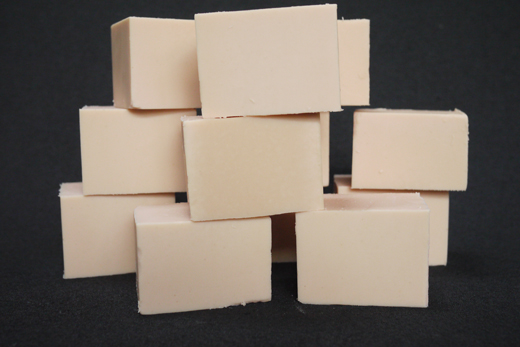

This three years soap has a good hardness but not enough to be a stone-like hardness, pressing hard enough to sell, but gives no breaks. The hardness is somewhat lower than conventional soap with olive, coconut and palm with the same drying time.

The foam remains difficult development and small and very easy soap dissolves on contact with water leaving some cream on the surface of the soap.

Compared with a conventional soap with olive, coconut and palm notice the big difference in the type of foam, large, abundant and easy development.

How is the soap after use.

What we can conclude is that, despite the long drying time and storage, the soap Castlla 100% olive made by cold process there is an improvement in the properties hearing over time.

Despite these shortcomings Castile Soap 100% Oliva by cold process, this soap is still unbeatable for sensitive skin and is widely used for bathing babies and children, for their high power conditioner.

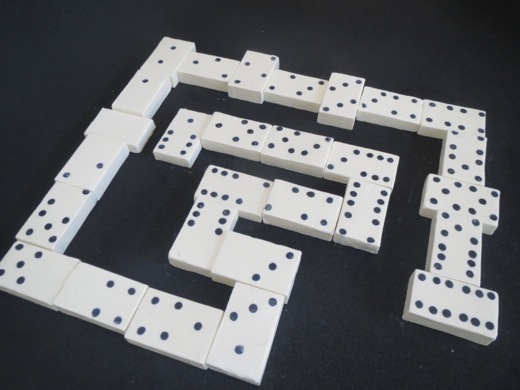

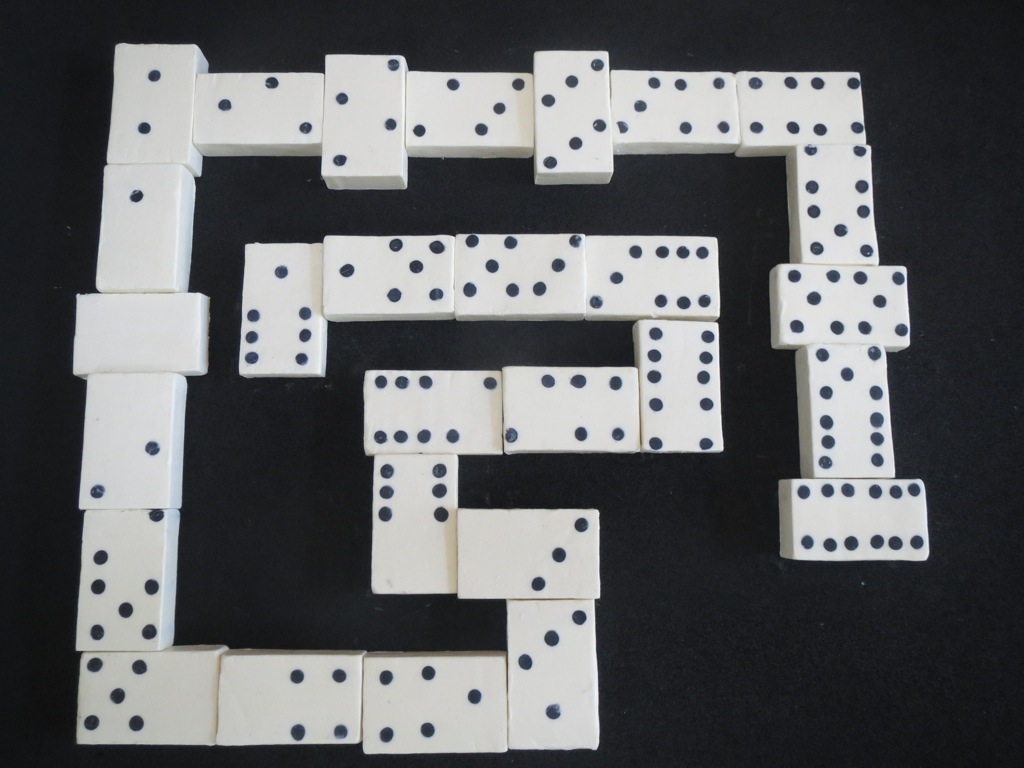

A variation of the same theme of the polka dots soaps, here’s the dominoes soaps. Soaps are basic formulation with palm oil / babassu oil / olive oil / castor oil – 35/30/30/5, SF 5%, lye concentration of 30% and titanium dioxide (1% o/o) and bamboo charcoal (1.5% o/o) to give, respectively, the white and black. Has been used for aroma essential oil of petitgrain / patchouli – 2/1, 3.5% o/o. It is the complete set of domino game with 28 soaps approx. 100g (8 x 5 cm).

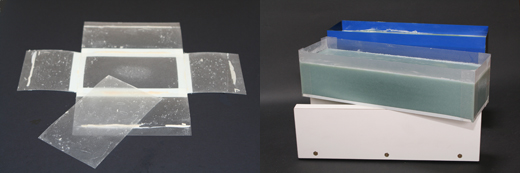

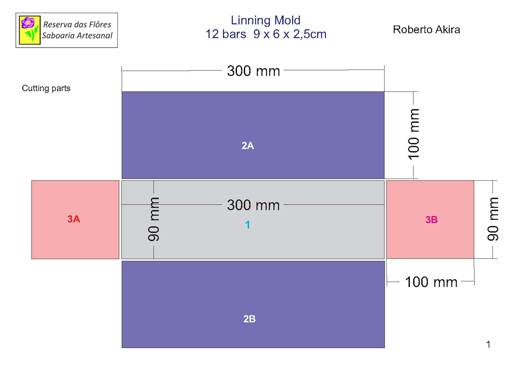

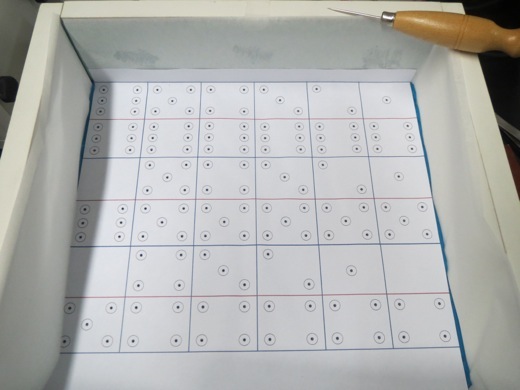

A variation of the same theme of the polka dots soaps, here’s the dominoes soaps. Soaps are basic formulation with palm oil / babassu oil / olive oil / castor oil – 35/30/30/5, SF 5%, lye concentration of 30% and titanium dioxide (1% o/o) and bamboo charcoal (1.5% o/o) to give, respectively, the white and black. Has been used for aroma essential oil of petitgrain / patchouli – 2/1, 3.5% o/o. It is the complete set of domino game with 28 soaps approx. 100g (8 x 5 cm). First are drawn every 28 domino game stones, sized for two molds, a 300 x 270 mm and one 300 x 180 mm, left a surplus in both molds. This generates a template for positioning on the modeling clay positioned at the bottom of the mold and marking.

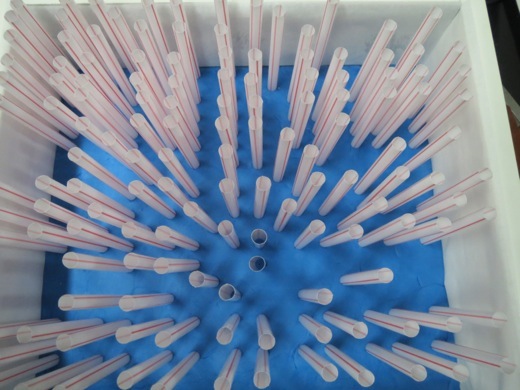

First are drawn every 28 domino game stones, sized for two molds, a 300 x 270 mm and one 300 x 180 mm, left a surplus in both molds. This generates a template for positioning on the modeling clay positioned at the bottom of the mold and marking. The soap is prepared with light trace and poured in molds. Had a problem caused by the acceleration of the trace due to the essential oil of lemon and the sudden increase in viscosity at the time of placing in the mold, the mold straws thrown down lower. I had to redo the two soap mold and prepare the small mold again.

The soap is prepared with light trace and poured in molds. Had a problem caused by the acceleration of the trace due to the essential oil of lemon and the sudden increase in viscosity at the time of placing in the mold, the mold straws thrown down lower. I had to redo the two soap mold and prepare the small mold again.

After 12 hours, the straws were removed.

After 12 hours, the straws were removed.

The black soap bamboo charcoal is prepared and 195 cavities are filled with this soap.

The black soap bamboo charcoal is prepared and 195 cavities are filled with this soap.

After 12 hours, the soap is removed from the molds and cut following the drawing of the template.

After 12 hours, the soap is removed from the molds and cut following the drawing of the template.