The most common vegetable oils that are used to make soap and handmade soaps are the same that are used in your kitchen or in the kitchens of the food industries. They are used in cooking and frying. The soybean, canola, sunflower and olive oils are most commonly used in homes, coconut in the regional cuisine and palm and palm kernel oil and in confectionery, sweets and in industrial frying.

All these oils are edible high consumption, used in domestic kitchen, are found in supermarkets. For marketing reasons must meet rigid standards of product presentation. Are standardized to be completely non-toxic and edible and shown as transparent and clear liquids, free from particles, without odor and high shelf life.

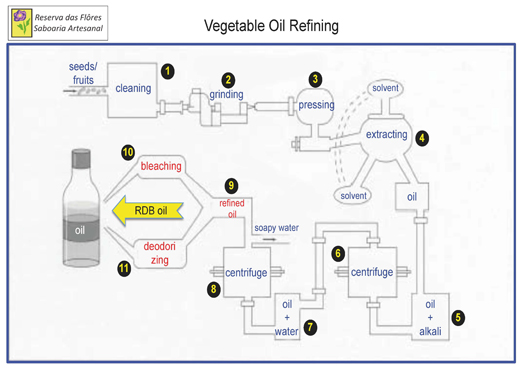

To achieve this patterning, oils and fats of vegetable origin require a specific processing. The processing that gives the generic name of refining. Vegetable oils are extracted from a variety of seeds, fruits and nuts. The preparation of the raw material starts with the washing and cleaning, followed by peeling, grinding and conditioning.

The extraction is generally done by mechanical means, and for fruit, distillation and seeds and nuts, the pressing with mechanical press. or the use of solvents such as hexane which is then distilled to separate the oil and is reused.

After extraction, to remove free fatty acids (FFA) that are responsible for the rapid deterioration of the oil and phospholipids (gum) which leaves the oil sticky, you need the refining process itself. There are two types of refining, physical refining when is used distillation (p ex. Palm oil) and chemical refining (most oils) when is used an alkali, usually sodium hydroxide, to neutralize free fatty acid.

The traditional method of refining is where the chemical diluted alkali saponified free fatty acids and is eliminated as soapy water. Besides the FFA is also eliminated phospholipids, metals, oxidized products, etc. In the physical method is required a step of degumming with acid, phosphoric acid or citric (p ex. Palm) to remove phospholipids. Below is a very simplified diagram of the process of solvent extraction and chemical refining.

The refined oil, where applicable, undergoes a process of bleaching with absorbing material (clay or activated charcoal) and deodorization process with steam.

In the final process has been called RDB oil (refined, bleached and deodorized).

The whole refining process of oil does not change the triglyceride composition, i.e. the composition of fatty acids. Thus the properties of the oil remains the same and the soap made of refined oil is the same, if applicable, ex p. olive oil or unrefined. Refining removes contaminants from oils dirds as FFA and phospholipids and some unrefined vegetable oils is even impossible to make a soap case of canola and soybean and palm.

It’s one of the myths of handmade soap manufacture, no problems with the soap made from refined oil, there is no restriction on the quantity and type, does not affect the properties of soap. Another urban legend is, in which oil extraction solvent was used, this solvent will be present in the soap! Another, in chemical refining using chemicals (NaOH) the lye that will be in the oil and hence will ruin the soap! The absurdity is that after the lye is used to make soap!

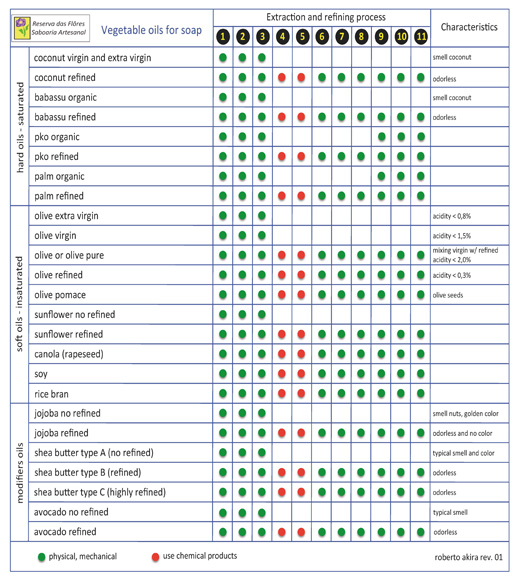

Below a relationship with key oils and butters used in soap manufacture craft and the type of processing for their purification. The numbering refers to the process of the previous diagram.

As you can see, some oils have the option of virgin and extra virgin means that the oil is no refining suffers, especially is the olive, and other options are organic, which means it is not used chemical refining, for ex. organic palm. Obviously these special types are much more expensive and difficult to find.

I emphasize again, there is no reason to choose virgin oils, extra virgin and organic to make soap. There is no difference between soap made with these types of oils and common refined.

Ola Roberto,

eu moro na Italia e tenho feito saboes com oleos extraidos com pressao mecanica, de otima qualidade mas caros. Gostaria de experimentar oleos usados na cozinha como girasol, soja etc., mas como sao refinados com hexanos ou outros produtos derivados do petroleo conhecidos como nocivos, gostaria de saber se saboes feitos com esse tipo de oleos contém restos de solventes que poderiam fazer mal à pele. Meu filho sofre de eczema e deve evitar produtos agressivos.Aguardo sua resposta. Parabéns por este site muito interessante!

Ely

Ely,

Absolutamente que os óleos refinados e a extração com solventes são seguros e a quantidade de solvente residual é da ordem de ppm (partes por milhão). Pode ser usados em sabão sem receio algum.