The mold in handmade cold process soap manufacture is intended to contain the fluid soap mass to do format and provide a stable saponification reaction, isolated from contact with the atmosphere, which reduces a possible carbonation (reaction of lye and carbon dioxide).

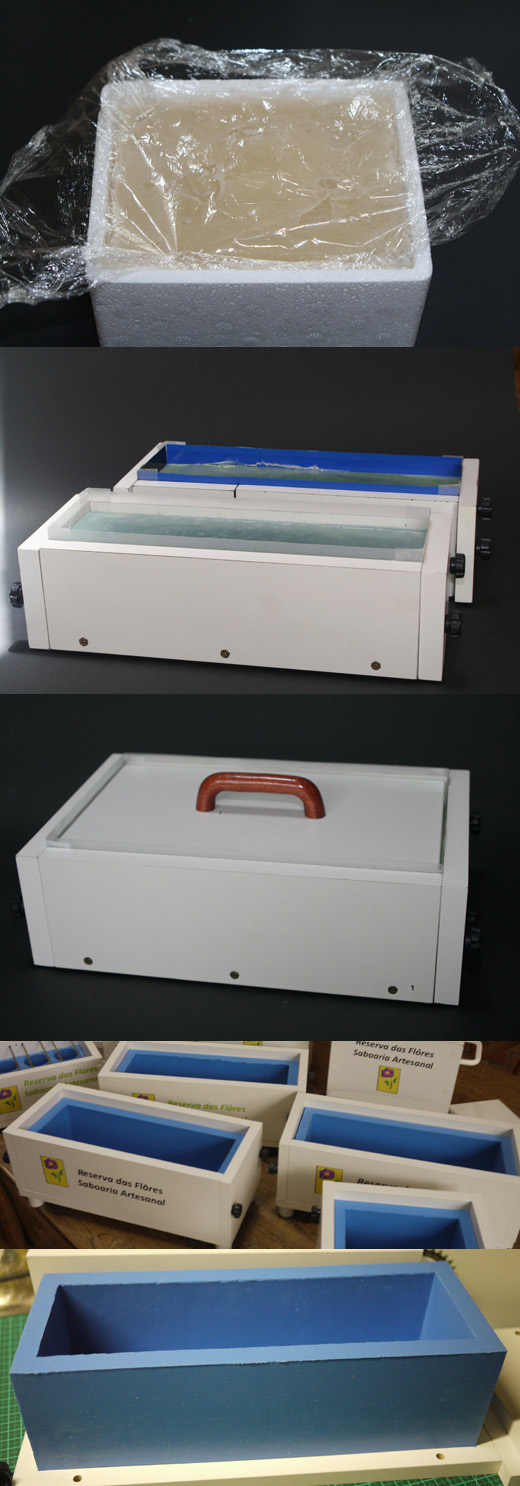

Technically, any material that fulfills the purpose of forming and which has a certain rigidity, it could be used as mold. A styrofoam box, those that are used for packing ice cream, fully lined, for example, with a pvc film for kitchen, serves perfectly as a mold. Another example could be a Tetra Pak carton of milk or juice. Anyway, there are many options to use as a mold. The most traditional is to use wood to make the molds. They may be simple wooden, plywood or MDF with melaminic or uncoated. All will require a liner to prevent the soap from sticking to the mold. The most sophisticated molds are made of silicone resin which is not necessary to liner due to anti-stick properties of the silicone and its chemical inertia.

Wood molds

I often use MDF double coated to make my molds. The MDF facilitates the work of an amateur woodworker for being an easy material cutting and drilling. The downside is the dust that rises when working material. Use type coated with a question of hygiene and ease of cleaning after use. I normally use MDF 18 or 15 mm thick, which is sufficient to maintain an adequate thermal insulation (I favor the formation of gel during the saponification). It’s simple to make a mold: the two larger side are fixed by screw at the bottom part and sides are removable witth the use of bolt and nuts embedded with canopy (1/4 “) and a cover of overlap. Dimensions are calculate to the size of soap you want. I have molds for 6, 12, 24 and 36 bars of soap with a thickness of 25 mm.

Silicone molds

I think it is worth the investment to make or buy silicone molds. Obviously it’s much more complicated than a simple wooden mold. You will need to learn to handle the silicone resin, which is not difficult and the biggest complication is the material or part that will be used as a template. The mold will have the shape of a bar of soap can be made of wood with melamine coating, as a box fully closed and well finished. I opted for convenience use a bar of aluminum, relatively expensive, having the facility to buy a supplier near here that cuts as you want. This greatly facilitated the work and the container is MDF box, a simple structure that will stand as support for silicone mold. You mount the box provisionally because the mold will need to unmold when ready, position the block of wood or aluminum block, fixed well underneath to prevent the resin to penetrate underneath, cover all inside area with solid vaseline and catalyzes the silcone resin. The ratio is specified by the manufacturer. Pours into the container with the block mold, cares not to form bubbles (add slowly to a reasonable height, expect the reaction and after about 6 hours you can unmold and your mold is ready, assemble the outer box and you can use the silicone mold, without lining!

Thank you !