Soap formulated with palm oil / babassu oil / olive oil / castor oil / cocoa butter – 30/30/30/5/5 with SF (superfating) 5%, lye concentration of 30%, 13 % (o/o) of solid chocolate bars with 70% cocoa and 0.7% (o/o) of 100% cocoa powder. The soap was decorated with the technique of straws with green pigment of chromium and titanium dioxide for green spots and aroma of 3% (o/o) of essential oil of peppermint. In the cocoa colored spots the red iron oxide was tinting with black iron oxide and titanium dioxide, and to give aroma, was used sweet orange essential oil 2% (o/o).

Soap formulated with palm oil / babassu oil / olive oil / castor oil / cocoa butter – 30/30/30/5/5 with SF (superfating) 5%, lye concentration of 30%, 13 % (o/o) of solid chocolate bars with 70% cocoa and 0.7% (o/o) of 100% cocoa powder. The soap was decorated with the technique of straws with green pigment of chromium and titanium dioxide for green spots and aroma of 3% (o/o) of essential oil of peppermint. In the cocoa colored spots the red iron oxide was tinting with black iron oxide and titanium dioxide, and to give aroma, was used sweet orange essential oil 2% (o/o).

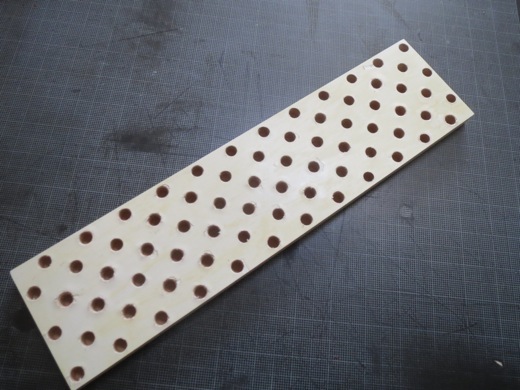

Was made this device that eliminates the use of modeling clay to hold the straws. It measures the mold and is attached to the bottom of the mold. The wells are 8.5 mm in diameter to hold 8 mm straws and has a depth of 12 mm.

Was made this device that eliminates the use of modeling clay to hold the straws. It measures the mold and is attached to the bottom of the mold. The wells are 8.5 mm in diameter to hold 8 mm straws and has a depth of 12 mm.

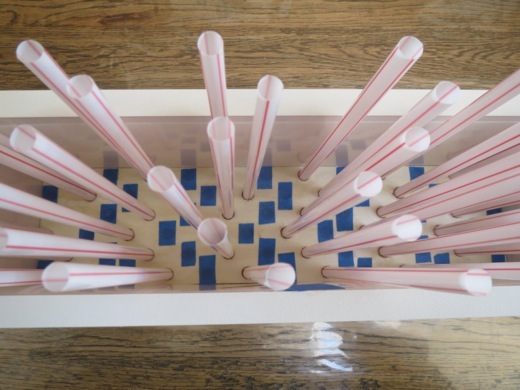

This mold was especially designed to allow to do 6 x 9 cm bars from 6 up to 24 bars (130g) using the technique of pipes.

This mold was especially designed to allow to do 6 x 9 cm bars from 6 up to 24 bars (130g) using the technique of pipes.

As this decoration was not used all the wells, those that are not used have been closed with tape (in blue).

As this decoration was not used all the wells, those that are not used have been closed with tape (in blue).

The chocolate is mixed with oils and cocoa butter and melted in the microwave.

The chocolate is mixed with oils and cocoa butter and melted in the microwave.

To use the technique of straws is important to leave a trace very light, which is added cocoa powder.

To use the technique of straws is important to leave a trace very light, which is added cocoa powder.

With the light trace is possible and even the mass of soap in the mold with the straws. The mold is in its maximum capacity as the mass is for 24 bars.

With the light trace is possible and even the mass of soap in the mold with the straws. The mold is in its maximum capacity as the mass is for 24 bars.

There was the formation of full gel and the surface temperature was 42 º C and after 6 hours the straws were removed when the temperature dropped to 32 º C.

There was the formation of full gel and the surface temperature was 42 º C and after 6 hours the straws were removed when the temperature dropped to 32 º C.

Despite the high temperature generated by the gel phase, there were no problems with surface irregularities such as cracks. This mold format favors the full gel when used at maximum capacity. Decoration was made as described above, with the very light mass trace.

Despite the high temperature generated by the gel phase, there were no problems with surface irregularities such as cracks. This mold format favors the full gel when used at maximum capacity. Decoration was made as described above, with the very light mass trace.

As mold lining was used a so-called opal plastic that is used to make lamps domes. Excellent plastic for this purpose.

As mold lining was used a so-called opal plastic that is used to make lamps domes. Excellent plastic for this purpose.

Using the vertical cutter was cut 3 mm from the top of the bar to eliminate the imperfections due to filling the cavities.

Using the vertical cutter was cut 3 mm from the top of the bar to eliminate the imperfections due to filling the cavities.

With the vertical cutter bar was cut into four smaller bars with a thickness of 23 mm.

With the vertical cutter bar was cut into four smaller bars with a thickness of 23 mm.

All smaller bars cut, no imperfection.

All smaller bars cut, no imperfection.

The individual bars was cut with individually cutter to all 24 bars standard size 6 x 9 cm.

The individual bars was cut with individually cutter to all 24 bars standard size 6 x 9 cm.